Mercedes radar recalibration is essential for vehicle safety and ADAS accuracy after repairs or accidents. Dynamic system testing recreates diverse driving conditions to verify radar performance, ensuring precise adjustments, improved car body repair quality, and enhanced overall vehicle safety. Calibrated test equipment, controlled environments, regular instrument maintenance, pre-recalibration inspections, and adherence to manufacturer guidelines ensure accurate results vital for road reliability.

Mercedes radar recalibration is a critical process ensuring optimal vehicle performance and safety. This article delves into the intricate details, starting with an understanding of the Mercedes radar recalibration process. We then explore the benefits of dynamic system testing for calibration, highlighting its precision and reliability. Finally, we offer best practices and tips to ensure accurate results, guiding readers through this essential maintenance step for their Mercedes vehicles.

- Understanding Mercedes Radar Recalibration Process

- Benefits of Dynamic System Testing for Calibration

- Ensuring Accurate Results: Best Practices and Tips

Understanding Mercedes Radar Recalibration Process

Mercedes radar recalibration is a critical process that ensures the safety and efficiency of modern vehicles. It involves adjusting and realigning the vehicle’s radar system to perform optimally, especially after certain events or conditions that might have affected its accuracy. This process is essential for maintaining the integrity of advanced driver-assistance systems (ADAS), such as collision avoidance and adaptive cruise control. By recalibrating the radar, Mercedes ensures that these safety features function correctly and provide reliable support to drivers in various driving scenarios.

When a vehicle undergoes significant repairs, especially involving the front end or the radar sensors, or after an auto collision center has repaired car damage, a dynamic system test is often required. This involves simulating real-world conditions to verify the radar’s performance. It includes testing the radar’s ability to detect and track objects at different speeds, angles, and distances. The process ensures that any adjustments made during recalibration are precise and effective, allowing for seamless integration of ADAS features, enhancing both car body repair quality and overall vehicle safety.

Benefits of Dynamic System Testing for Calibration

Dynamic System Testing offers a multitude of benefits when it comes to Mercedes radar recalibration. By simulating real-world driving conditions in a controlled environment, this method ensures precise and consistent calibration. It allows for thorough evaluation of the radar system’s performance across various scenarios, from low-speed maneuvers to high-speed turns, enhancing safety features like collision avoidance and adaptive cruise control.

Furthermore, Dynamic System Testing enables the identification of subtle issues that might be overlooked in static testing. This proactive approach to car collision repair and general auto repair services contributes to better overall vehicle performance and reliability, ultimately enhancing customer satisfaction with the car bodywork and its advanced driver assistance systems.

Ensuring Accurate Results: Best Practices and Tips

Achieving accurate results during Mercedes radar recalibration is paramount to ensure safety and reliability on the road. To accomplish this, best practices include using calibrated test equipment that meets industry standards, performing tests in controlled environments mimicking real-world driving conditions, and regularly maintaining and calibrating instruments for optimal performance.

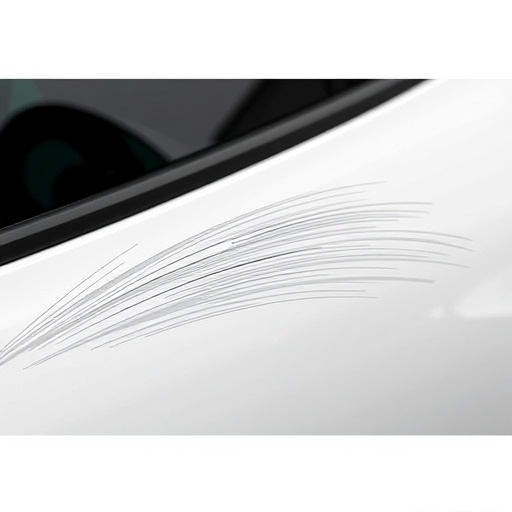

Before initiating any recalibration process, thorough inspection of the vehicle, particularly after incidents like a fender bender or car scratch repair in a vehicle body shop, is crucial to rule out any physical damage that might interfere with radar accuracy. Maintaining a clean and clear sensor area, free from debris or obstructions, is also essential for precise measurements. Additionally, adhering to manufacturer guidelines and seeking assistance from trained professionals ensures the recalibration process aligns with Mercedes’ stringent quality control measures.

Mercedes radar recalibration is a critical process ensuring the safety and efficiency of modern vehicles. Dynamic system testing, with its ability to simulate real-world conditions, proves invaluable in verifying accurate results. By adhering to best practices and leveraging dynamic testing, auto manufacturers like Mercedes can confidently enhance their systems’ performance and reliability, ultimately contributing to improved driving experiences.